Lift Pins

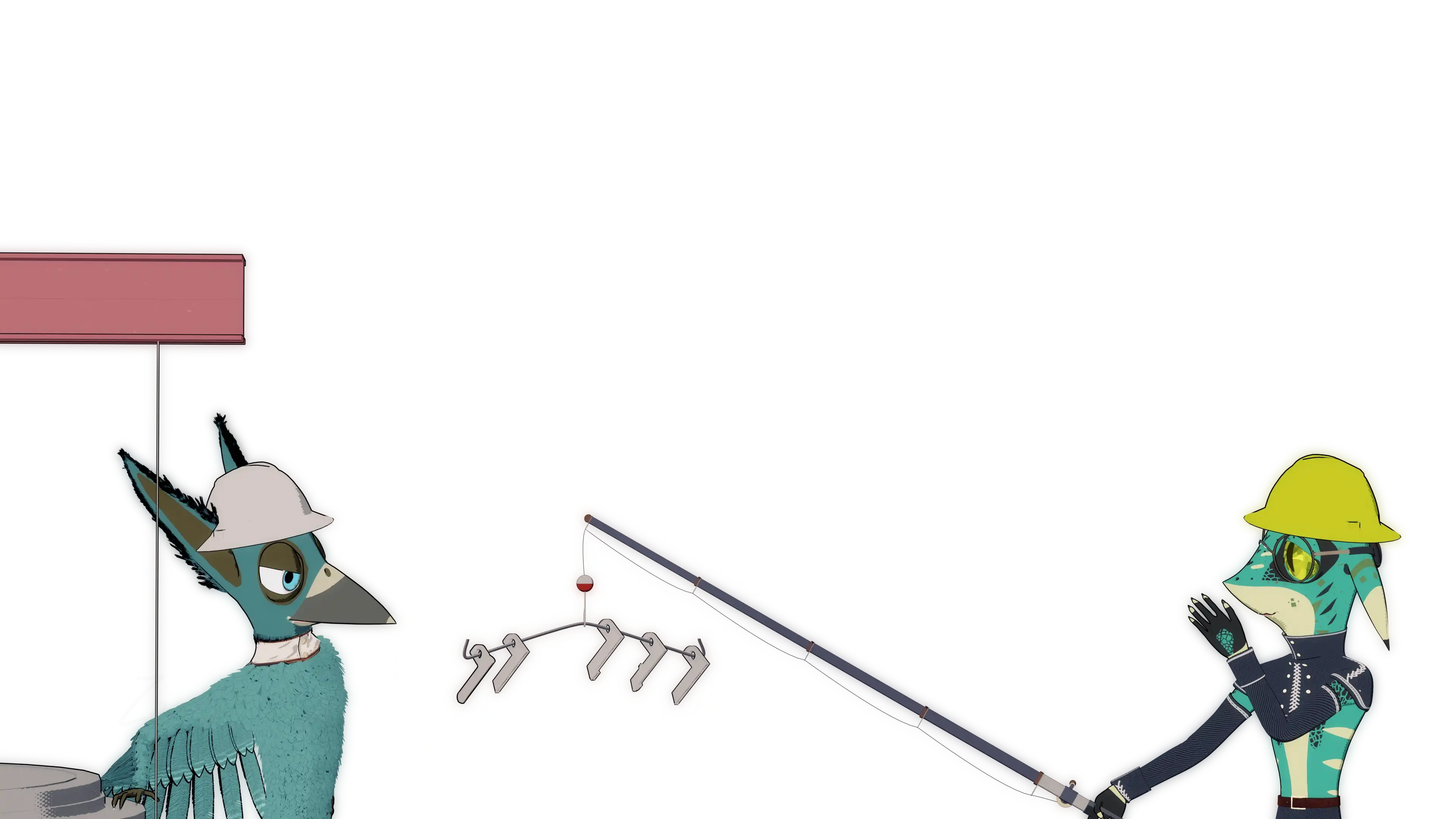

Characters Tools

This was for a presentation about new possible designs for lifting pins at my work. We have large concrete products that need special lifting equipment to move around, but the pins that were in current use had safety issues associated with them. As part of this presentation, I demonstrated the safety issue associated with the current design and introduced other design concepts to replace this in the future. While it wasn’t required, I drafted up two characters in construction uniform to more comically demonstrate the safety issues and new design suggestions.

First was to demonstrate the hazard inherent to the existing design. We have a relatively standard lifting setup shown for large cylindrical products. The lift-pins are inserted into plastic recesses on opposites sides of the product, and lifting straps and shackles connect the pins to an overhead spreader bar.

The spreader bar would be lifted by another lifting machine such as a boom-truck or overhead crane (not shown), and this would correspondingly hoist the product into the air. However, issue existing with the current pins was that there was no explicit locking mechanism. The pins were simply cylinders with lift-attachment points, and they would slide into closely-sized hollow inserts cast into the product. The only thing holding the pins in place would be the friction of the pin against the insides. While in the majority of cases this friction would keep the pins locked in place, there’s a chance for at least one of the pins to slip out under certain motions.

Of course, the end result is a possible safety disaster. Aside from the loose pin possibly flying out at quick speed, there is also a several-thousand pound object quickly swinging towards the ground. Of course, this possibility had been raising concerns with the company executives, so engineering was to come up with new designs to replace this.

On top of this safety issue with the design, the supplier for pins was back-ordered for several months. It was decided to have production take place in-house to avoid these supply issues.

As for in-house production, there was a similar design introduced that was simply a flat-version of the existing design. This could quickly be laser-cut from a thick sheet of metal and machined to the final dimensions around its edges. However, this too would retain the safety issues of the current service lift-pin.

So, other designs would still have to be considered, and maybe we could stop chucking items across the room too!

As the designs themselves may have been proprietary, I will not discuss them in detail here. One design idea though would’ve had issues upon insertion and removal, and the workers were again shown demonstrating these possible difficulties.

All renders were made in Blender and rendered with Blender Cycles. Further Image Post-Processing was done with Krita.