Craneway

Characters Environments Tools

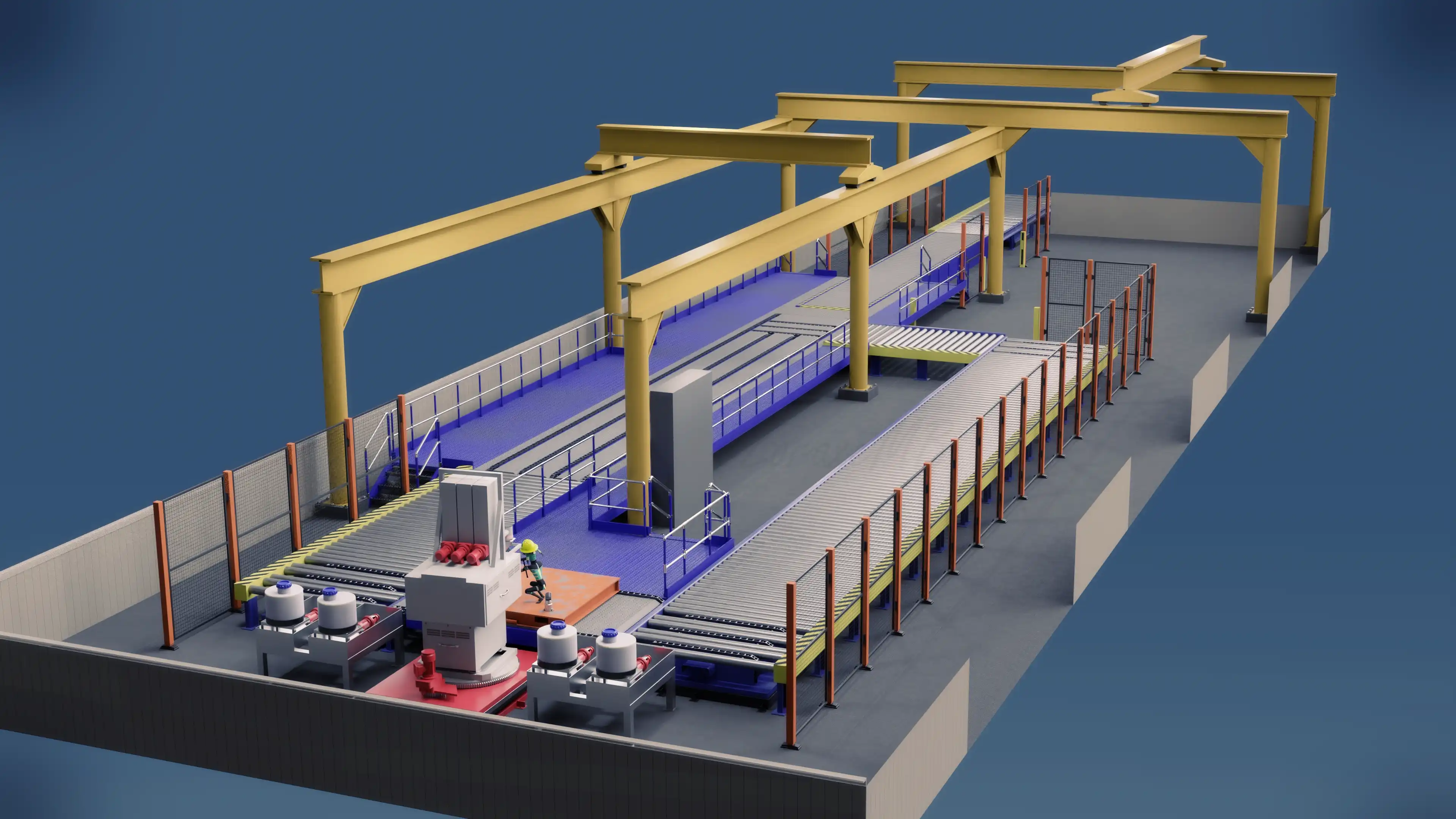

As part of the possibility for making training videos, a large portion of a manufacturing facility for polymer-concrete production was recreated digitally. This included the mixing machine, the conveyor-belt system, and overhead cranes. While there wasn't much done with it in the end, it's still a worthy piece to present. This first image gives a good view of the whole facility. The mixing machine is at one end of the conveyor system, and there is slight indication that it's being "worked on" by my character workers. The conveyor system is composed mostly of rolling pins and chain drives meant to move trays with casting molds around. Representations of the overhead cranes are shown with their yellow-painted beams and bridges.

Around areas where the molds are handled, there is ample floor space to allow for work to be done. Of course, this is a relatively empty view of the space before more people and tool boxes were moved in to perform work.

At every corner were these lift-table that contained their own set of transfer chains. When a tray rolled into a corner, this table would raise up and push the tray against these chains. They would then transfer the mold-tray horizontally to the next set of rollers. This procedure was done at all four corners of the conveyor line to move trays around in a circular flow.

At the center of production was the mixer machine, there were certainly problems in getting it commissioned. The machine was excellent with most forms of polymer concrete, but the supplied methods for introducing chopped glass fibers into the mix was causing issues. This render here was to commemorate a moment of clogging during the research & development phase. Polymer concrete hardens in less than an hour, so a clog in the mixer that couldn't be cleared in time could spell disaster. In this case, the main screw had clogged and polymer concrete hardened. We loosened the fasteners holding the large mixing screw in at the rear and proceeded to remove it thread-by-thread with a crowbar while chiseling the exposed pieces off. Quite an involved process.

While it was aggrevating from time-to-time, it was quite a learning experience! It was worthwhile to get hands-on experience with machinery like all this alongside digitally recreating it as shown here.

Made with Blender, rendered with the Blender Cycles Render Engine.